Key Takeaways

- IIT researchers discovered tetrapod-shaped nanoparticles reduce plastic viscosity by up to 40%

- This breakthrough could significantly lower energy consumption in plastic manufacturing

- Unlike spherical nanoparticles that thicken plastics, tetrapods create unique flow-enhancing effects

In a groundbreaking discovery, researchers from IIT Bombay, IIT Madras, and IIT Kanpur have found that tetrapod-shaped nanoparticles can dramatically reduce plastic viscosity, potentially revolutionizing plastic manufacturing processes. This innovation could lead to substantial energy savings and more efficient production methods across the plastics industry.

The Viscosity Challenge in Plastics

While polymers give plastics their versatile properties, their long molecular chains often create extremely thick, viscous materials when melted. This high viscosity makes processing difficult, energy-intensive, and costly for many industrial applications.

Breakthrough Research Methodology

The collaborative study, titled ‘Nanotetrapods promote polymer flow through confinement induced packing frustration,’ tested tetrapod-shaped nanoparticles in polystyrene. The research team included Professor Mithun Chowdhury (IIT Bombay), Professors Anindya Datta (IIT Bombay), Tarak K. Patra (IIT Madras), and Sivasurender Chandran (IIT Kanpur).

“This study opens a pathway to potentially lower processing energy in the future, if we can mass synthesise precisely shaped sustainable nanoparticles,” said Professor Chowdhury.

Marine Inspiration Leads to Scientific Innovation

The research concept originated from a casual observation during a walk along Marine Drive. “We saw the large concrete tetrapods used to break waves. That sparked a question: what if we used tiny versions of these shapes in thick polymer fluids?” explained Professor Chowdhury.

How Tetrapods Reduce Viscosity

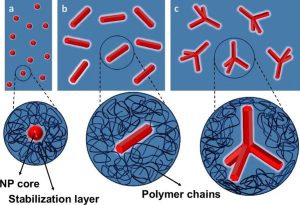

Unlike spherical or rod-shaped nanoparticles that typically increase viscosity, tetrapods create unique geometric effects:

- Inner curvatures create regions polymer chains avoid

- Reduces polymer density around nanoparticles

- Enables easier sliding of polymer chains past each other

“The simulations showed that the inner curvatures of a tetrapod create regions that long polymer chains find unfavourable to enter,” Professor Chowdhury elaborated.

Experimental Validation and Results

Using cadmium-selenium tetrapods from Professor Datta’s lab, the team confirmed that only tetrapod shapes improved flow without compromising the polymer’s mechanical or thermal properties. Control experiments with spherical and rod-shaped nanoparticles validated these unique effects.

Future Applications and Challenges

The technology shows promise for various applications including coatings, adhesives, and 3D printing resins where specific viscosity control is crucial. However, challenges remain in scaling up nanoparticle synthesis and replacing toxic cadmium with eco-friendly alternatives.

The research team is now exploring adaptation to different polymers and developing AI models to predict flow behavior based on nanoparticle geometry.